Current Articles

Display Method: |

2024, 37: 12.

doi: 10.1186/s10033-024-00994-x

Abstract:

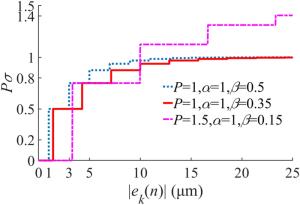

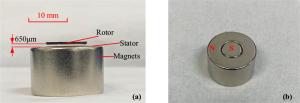

This paper proposes a modified iterative learning control (MILC) periodical feedback-feedforward algorithm to reduce the vibration of a rotor caused by coupled unbalance and parallel misalignment. The control of the vibration of the rotor is provided by an active magnetic actuator (AMA). The iterative gain of the MILC algorithm here presented has a self-adjustment based on the magnitude of the vibration. Notch filters are adopted to extract the synchronous (1 × Ω) and twice rotational frequency (2 × Ω) components of the rotor vibration. Both the notch frequency of the filter and the size of feedforward storage used during the experiment have a real-time adaptation to the rotational speed. The method proposed in this work can provide effective suppression of the vibration of the rotor in case of sudden changes or fluctuations of the rotor speed. Simulations and experiments using the MILC algorithm proposed here are carried out and give evidence to the feasibility and robustness of the technique proposed.

This paper proposes a modified iterative learning control (MILC) periodical feedback-feedforward algorithm to reduce the vibration of a rotor caused by coupled unbalance and parallel misalignment. The control of the vibration of the rotor is provided by an active magnetic actuator (AMA). The iterative gain of the MILC algorithm here presented has a self-adjustment based on the magnitude of the vibration. Notch filters are adopted to extract the synchronous (1 × Ω) and twice rotational frequency (2 × Ω) components of the rotor vibration. Both the notch frequency of the filter and the size of feedforward storage used during the experiment have a real-time adaptation to the rotational speed. The method proposed in this work can provide effective suppression of the vibration of the rotor in case of sudden changes or fluctuations of the rotor speed. Simulations and experiments using the MILC algorithm proposed here are carried out and give evidence to the feasibility and robustness of the technique proposed.

2024, 37: 52.

doi: 10.1186/s10033-024-01030-8

Abstract:

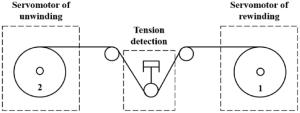

A winding system is a time-varying system that considers complex nonlinear characteristics, and how to control the stability of the winding tension during the winding process is the primary problem that has hindered development in this field in recent years. Many nonlinear factors affect the tension in the winding process, such as friction, structured uncertainties, unstructured uncertainties, and external interference. These terms severely restrict the tension tracking performance. Existing tension control strategies are mainly based on the composite control of the tension and speed loops, and previous studies involve complex decoupling operations. Owing to the large number of calculations required for this method, it is inconvenient for practical engineering applications. To simplify the tension generation mechanism and the influence of the nonlinear characteristics of the winding system, a simpler nonlinear dynamic model of the winding tension was established. An adaptive method was applied to update the feedback gain of the continuous robust integral of the sign of the error (RISE). Furthermore, an extended state observer was used to estimate modeling errors and external disturbances. The model disturbance term can be compensated for in the designed RISE controller. The asymptotic stability of the system was proven according to the Lyapunov stability theory. Finally, a comparative analysis of the proposed nonlinear controller and several other controllers was performed. The results indicated that the control of the winding tension was significantly enhanced.

A winding system is a time-varying system that considers complex nonlinear characteristics, and how to control the stability of the winding tension during the winding process is the primary problem that has hindered development in this field in recent years. Many nonlinear factors affect the tension in the winding process, such as friction, structured uncertainties, unstructured uncertainties, and external interference. These terms severely restrict the tension tracking performance. Existing tension control strategies are mainly based on the composite control of the tension and speed loops, and previous studies involve complex decoupling operations. Owing to the large number of calculations required for this method, it is inconvenient for practical engineering applications. To simplify the tension generation mechanism and the influence of the nonlinear characteristics of the winding system, a simpler nonlinear dynamic model of the winding tension was established. An adaptive method was applied to update the feedback gain of the continuous robust integral of the sign of the error (RISE). Furthermore, an extended state observer was used to estimate modeling errors and external disturbances. The model disturbance term can be compensated for in the designed RISE controller. The asymptotic stability of the system was proven according to the Lyapunov stability theory. Finally, a comparative analysis of the proposed nonlinear controller and several other controllers was performed. The results indicated that the control of the winding tension was significantly enhanced.

2024, 37: 91.

doi: 10.1186/s10033-024-01066-w

Abstract:

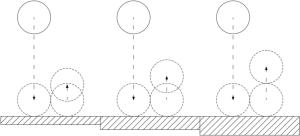

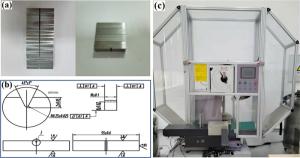

Collisions between objects are a relatively common phenomenon in nature. Analyses of collision processes can greatly contribute to solving problems such as impact-rub faults and particle impacts. The coefficient of restitution is a critical parameter in the analysis of collision processes. Many experiments have shown that the coefficient of restitution is closely related to the plate thickness, and the smaller the plate thickness, the more inaccurate the coefficient of restitution predicted by the existing model, which seriously affects the process of collision analysis. To remedy this shortcoming, this paper proposes a plate thickness influence factor with the ratio of sphere diameter to plate thickness as the variable. The plate thickness influence factor can optimize the coefficient of restitution model to effectively predict the coefficient of restitution of impacting elastoplastic spheres with finite plate thickness. Finally, the validity of the new model is verified using a large amount of experimental data.

Collisions between objects are a relatively common phenomenon in nature. Analyses of collision processes can greatly contribute to solving problems such as impact-rub faults and particle impacts. The coefficient of restitution is a critical parameter in the analysis of collision processes. Many experiments have shown that the coefficient of restitution is closely related to the plate thickness, and the smaller the plate thickness, the more inaccurate the coefficient of restitution predicted by the existing model, which seriously affects the process of collision analysis. To remedy this shortcoming, this paper proposes a plate thickness influence factor with the ratio of sphere diameter to plate thickness as the variable. The plate thickness influence factor can optimize the coefficient of restitution model to effectively predict the coefficient of restitution of impacting elastoplastic spheres with finite plate thickness. Finally, the validity of the new model is verified using a large amount of experimental data.

2024, 37: 8.

doi: 10.1186/s10033-023-00989-0

Abstract:

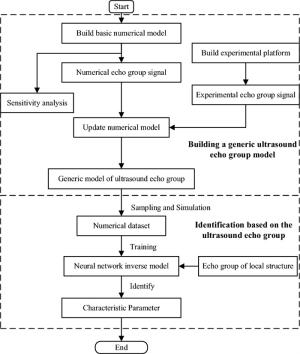

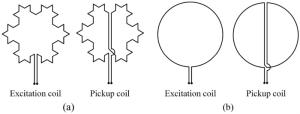

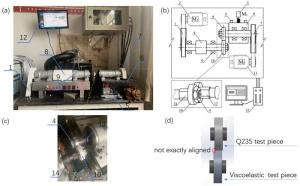

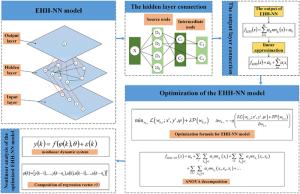

On-site and real-time non-destructive measurement of elastic constants for materials of a component in a in-service structure is a challenge due to structural complexities, such as ambiguous boundary, variable thickness, nonuniform material properties. This work develops for the first time a method that uses ultrasound echo groups and artificial neural network (ANN) for reliable on-site real-time identification of material parameters. The use of echo groups allows the use of lower frequencies, and hence more accommodative to structural complexity. To train the ANNs, a numerical model is established that is capable of computing the waveform of ultrasonic echo groups for any given set of material properties of a given structure. The waveform of an ultrasonic echo groups at an interest location on the surface the structure with material parameters varying in a predefined range are then computed using the numerical model. This results in a set of dataset for training the ANN model. Once the ANN is trained, the material parameters can be identified simultaneously using the actual measured echo waveform as input to the ANN. Intensive tests have been conducted both numerically and experimentally to evaluate the effectiveness and accuracy of the currently proposed method. The results show that the maximum identification error of numerical example is less than 2%, and the maximum identification error of experimental test is less than 7%. Compared with currently prevailing methods and equipment, the proposefy the density and thickness, in addition to the elastic constants. Moreover, the reliability and accuracy of inverse prediction is significantly improved. Thus, it has broad applications and enables real-time field measurements, which has not been fulfilled by any other available methods or equipment.

On-site and real-time non-destructive measurement of elastic constants for materials of a component in a in-service structure is a challenge due to structural complexities, such as ambiguous boundary, variable thickness, nonuniform material properties. This work develops for the first time a method that uses ultrasound echo groups and artificial neural network (ANN) for reliable on-site real-time identification of material parameters. The use of echo groups allows the use of lower frequencies, and hence more accommodative to structural complexity. To train the ANNs, a numerical model is established that is capable of computing the waveform of ultrasonic echo groups for any given set of material properties of a given structure. The waveform of an ultrasonic echo groups at an interest location on the surface the structure with material parameters varying in a predefined range are then computed using the numerical model. This results in a set of dataset for training the ANN model. Once the ANN is trained, the material parameters can be identified simultaneously using the actual measured echo waveform as input to the ANN. Intensive tests have been conducted both numerically and experimentally to evaluate the effectiveness and accuracy of the currently proposed method. The results show that the maximum identification error of numerical example is less than 2%, and the maximum identification error of experimental test is less than 7%. Compared with currently prevailing methods and equipment, the proposefy the density and thickness, in addition to the elastic constants. Moreover, the reliability and accuracy of inverse prediction is significantly improved. Thus, it has broad applications and enables real-time field measurements, which has not been fulfilled by any other available methods or equipment.

2024, 37: 25.

doi: 10.1186/s10033-024-01011-x

Abstract:

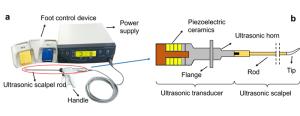

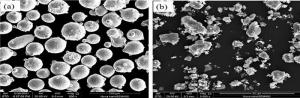

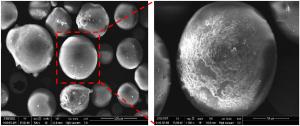

Minimum quantity Lubrication (MQL) is a sustainable lubrication system that is famous in many machining systems. It involve the spray of an infinitesimal amount of mist-like lubricants during machining processes. The MQL system is affirmed to exhibit an excellent machining performance, and it is highly economical. The nanofluids are understood to exhibit excellent lubricity and heat evacuation capability, compared to pure oil-based MQL system. Studies have shown that the surface quality and amount of energy expended in the grinding operations can be reduced considerably due to the positive effect of these nanofluids. This work presents an experimental study on the tribological performance of SiO2 nanofluid during grinding of Si3N4 ceramic. The effect different grinding modes and lubrication systems during the grinding operation was also analyzed. Different concentrations of the SiO2 nanofluid was manufactured using canola, corn and sunflower oils. The quantitative evaluation of the grinding process was done based on the amount of grinding forces, specific grinding energy, frictional coefficient, and surface integrity. It was found that the canola oil exhibits optimal lubrication performance compared to corn oil, sunflower oil, and traditional lubrication systems. Additionally, the introduction of ultrasonic vibrations with the SiO2 nanofluid in MQL system was found to reduce the specific grinding energy, normal grinding forces, tangential grinding forces, and surface roughness by 65%, 57%, 65%, and 18% respectively. Finally, regression analysis was used to obtain an optimum parameter combinations. The observations from this work will aid the smooth transition towards ecofriendly and sustainable machining of engineering ceramics.

Minimum quantity Lubrication (MQL) is a sustainable lubrication system that is famous in many machining systems. It involve the spray of an infinitesimal amount of mist-like lubricants during machining processes. The MQL system is affirmed to exhibit an excellent machining performance, and it is highly economical. The nanofluids are understood to exhibit excellent lubricity and heat evacuation capability, compared to pure oil-based MQL system. Studies have shown that the surface quality and amount of energy expended in the grinding operations can be reduced considerably due to the positive effect of these nanofluids. This work presents an experimental study on the tribological performance of SiO2 nanofluid during grinding of Si3N4 ceramic. The effect different grinding modes and lubrication systems during the grinding operation was also analyzed. Different concentrations of the SiO2 nanofluid was manufactured using canola, corn and sunflower oils. The quantitative evaluation of the grinding process was done based on the amount of grinding forces, specific grinding energy, frictional coefficient, and surface integrity. It was found that the canola oil exhibits optimal lubrication performance compared to corn oil, sunflower oil, and traditional lubrication systems. Additionally, the introduction of ultrasonic vibrations with the SiO2 nanofluid in MQL system was found to reduce the specific grinding energy, normal grinding forces, tangential grinding forces, and surface roughness by 65%, 57%, 65%, and 18% respectively. Finally, regression analysis was used to obtain an optimum parameter combinations. The observations from this work will aid the smooth transition towards ecofriendly and sustainable machining of engineering ceramics.

2024, 37: 161.

doi: 10.1186/s10033-024-01156-9

Abstract:

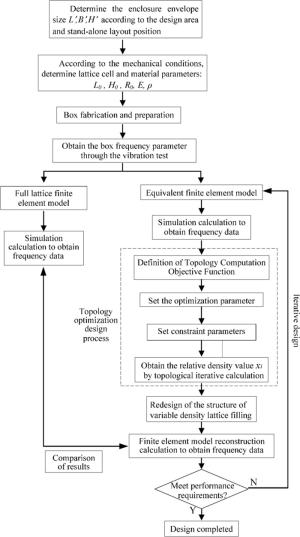

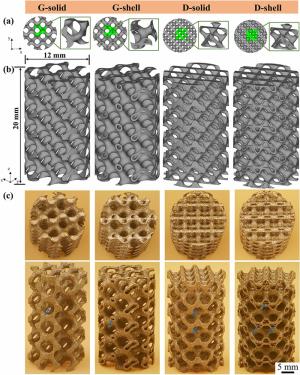

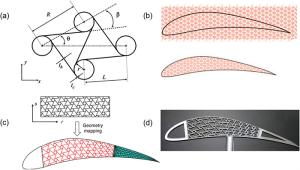

Traditional structural forms are difficult to meet the lightweight requirements of subsequent spacecraft for load-bearing structures. In the aerospace industry, filling structure with lattices is a popular approach to reduce the weight of a spacecraft. However, this design strategy has deficiencies in the spatial distribution of lattice cells as well as its affection on the mechanical properties. In this study, a two-step topology optimization technique is proposed to solve the spatial distribution problem of nanosatellite. Firstly, an entire nanosatellite box composed of panels which filled with uniform lattices is sent to the vibration test to obtain the frequency data. Then, a finite element (FE) model of the nanosatellite structure which contains the same uniform lattices is built and validated with the obtained frequency data above. For the subsequent calculation of topology optimization. An equivalent model of the verified FE model is established by replacing the lattice cells in the sandwich layer with equivalent fictional elements. Subsequently, a topology optimization problem under the mass constraints is formulated for maximize the nature frequency, and a new light weighted nanosatellite which filled with non-uniform lattices is established by applying the density mapping method and the previous topology configuration result. By separating the design problem of nanosatellite into two steps, the proposed optimization design method achieves the maximum frequency design under the weight constraint. Furthermore, the frequency is also guaranteed to be around the nature frequency. The results reveal that the mass of the new structure with non-uniform lattices is reduced by 50.32% and the frequency is increased by 1.19%. An important technical importance and application value of this proposed technique is that it improves the performance and design efficiency of the load-bearing structures of a nanosatellite, and this method has significant technical significance and application value.

Traditional structural forms are difficult to meet the lightweight requirements of subsequent spacecraft for load-bearing structures. In the aerospace industry, filling structure with lattices is a popular approach to reduce the weight of a spacecraft. However, this design strategy has deficiencies in the spatial distribution of lattice cells as well as its affection on the mechanical properties. In this study, a two-step topology optimization technique is proposed to solve the spatial distribution problem of nanosatellite. Firstly, an entire nanosatellite box composed of panels which filled with uniform lattices is sent to the vibration test to obtain the frequency data. Then, a finite element (FE) model of the nanosatellite structure which contains the same uniform lattices is built and validated with the obtained frequency data above. For the subsequent calculation of topology optimization. An equivalent model of the verified FE model is established by replacing the lattice cells in the sandwich layer with equivalent fictional elements. Subsequently, a topology optimization problem under the mass constraints is formulated for maximize the nature frequency, and a new light weighted nanosatellite which filled with non-uniform lattices is established by applying the density mapping method and the previous topology configuration result. By separating the design problem of nanosatellite into two steps, the proposed optimization design method achieves the maximum frequency design under the weight constraint. Furthermore, the frequency is also guaranteed to be around the nature frequency. The results reveal that the mass of the new structure with non-uniform lattices is reduced by 50.32% and the frequency is increased by 1.19%. An important technical importance and application value of this proposed technique is that it improves the performance and design efficiency of the load-bearing structures of a nanosatellite, and this method has significant technical significance and application value.

2024, 37: 164.

doi: 10.1186/s10033-024-01154-x

Abstract:

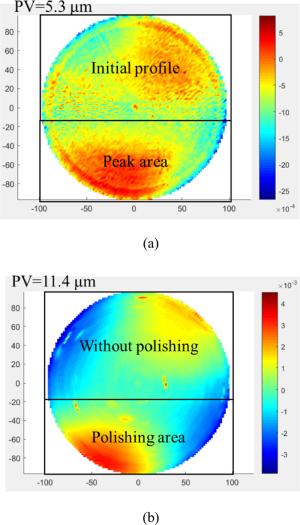

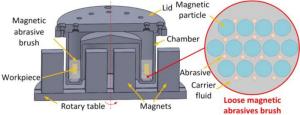

Thin copper substrates with high accuracy are highly required in precision physical experiments. However, even using double-sided lapping, the flatness is still limited due to the accuracy of lapping plate, process vibration and so on. Hence, as a subsequent process, this paper employs magnetorheological finishing (MRF) to further improve the flatness. Nevertheless, thin copper substrates, which are sensitive to the stress, deformed easily with uneven material removal on the surface. Therefore, MRF is adopted on machining thin copper substrate for the first time considering deformation induced by stress. A finite element model is established to evaluate the deformation by residual stress, and the results show that the deformation tends to be more serious with the increase of the material removal. According to the simulation results, the material removal is optimized considering both deformation and efficiency, and a series of experiments are conducted on a Φ100×2.8 mm workpiece to verify the simulation results. The experimental results show that the flatness is further improved from peak to valley (PV) 6.6 μm to PV 2.3 μm with optimized processing parameters. Hence, the feasibility of magnetorheological finishing on thin copper substrate is demonstrated.

Thin copper substrates with high accuracy are highly required in precision physical experiments. However, even using double-sided lapping, the flatness is still limited due to the accuracy of lapping plate, process vibration and so on. Hence, as a subsequent process, this paper employs magnetorheological finishing (MRF) to further improve the flatness. Nevertheless, thin copper substrates, which are sensitive to the stress, deformed easily with uneven material removal on the surface. Therefore, MRF is adopted on machining thin copper substrate for the first time considering deformation induced by stress. A finite element model is established to evaluate the deformation by residual stress, and the results show that the deformation tends to be more serious with the increase of the material removal. According to the simulation results, the material removal is optimized considering both deformation and efficiency, and a series of experiments are conducted on a Φ100×2.8 mm workpiece to verify the simulation results. The experimental results show that the flatness is further improved from peak to valley (PV) 6.6 μm to PV 2.3 μm with optimized processing parameters. Hence, the feasibility of magnetorheological finishing on thin copper substrate is demonstrated.

2024, 37: 86.

doi: 10.1186/s10033-024-01068-8

Abstract:

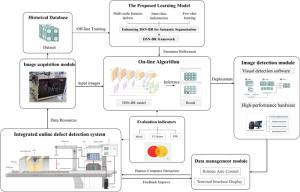

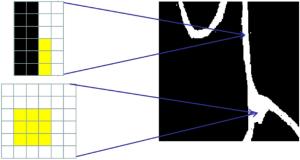

Ensuring high product quality is of paramount importance in pharmaceutical drug manufacturing, as it is subject to rigorous regulatory practices. This study presents a research focused on the development of an on-line detection method and system for identifying surface defects in pharmaceutical products packaged in aluminum-plastic blisters. Firstly, the aluminum-plastic blister packages exhibit multi-scale features and inter-class indistinction. To address this, the deep semantic network with boundary refinement (DSN-BR) model is proposed, which leverages semantic segmentation domain knowledge, to accurately segment the defects in pixel level. Additionally, a specialized image acquisition module that minimizes the impact of ambient light is established, ensuring high-quality image capture. Finally, the image acquisition module, image detection module, and data management module are designed to construct a comprehensive online surface defect detection system. To validate the effectiveness of our approach, we employ a real dataset for instance verification on the implemented system. The experimental results substantiate the outstanding performance of the DSN-BR, achieving the mean intersection over union (MIoU) of 90.5%. Furthermore, the proposed system achieves an inference speed of up to 14.12 f/s, while attaining an F1-Score of 98.25%. These results demonstrate that the system meets the actual needs of the enterprise and provides theoretical and methodological support for intelligent inspection of product surface quality. By standardizing the control process of pharmaceutical manufacturing and improving the management capability of the manufacturing process, our approach holds significant market application prospects.

Ensuring high product quality is of paramount importance in pharmaceutical drug manufacturing, as it is subject to rigorous regulatory practices. This study presents a research focused on the development of an on-line detection method and system for identifying surface defects in pharmaceutical products packaged in aluminum-plastic blisters. Firstly, the aluminum-plastic blister packages exhibit multi-scale features and inter-class indistinction. To address this, the deep semantic network with boundary refinement (DSN-BR) model is proposed, which leverages semantic segmentation domain knowledge, to accurately segment the defects in pixel level. Additionally, a specialized image acquisition module that minimizes the impact of ambient light is established, ensuring high-quality image capture. Finally, the image acquisition module, image detection module, and data management module are designed to construct a comprehensive online surface defect detection system. To validate the effectiveness of our approach, we employ a real dataset for instance verification on the implemented system. The experimental results substantiate the outstanding performance of the DSN-BR, achieving the mean intersection over union (MIoU) of 90.5%. Furthermore, the proposed system achieves an inference speed of up to 14.12 f/s, while attaining an F1-Score of 98.25%. These results demonstrate that the system meets the actual needs of the enterprise and provides theoretical and methodological support for intelligent inspection of product surface quality. By standardizing the control process of pharmaceutical manufacturing and improving the management capability of the manufacturing process, our approach holds significant market application prospects.

2024, 37: 1.

doi: 10.1186/s10033-023-00972-9

Abstract:

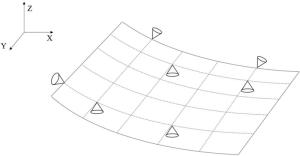

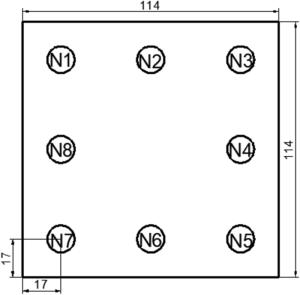

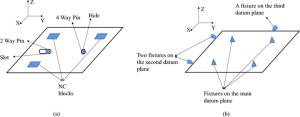

There are lots of researches on fixture layout optimization for large thin-walled parts. Current researches focus on the positioning problem, i.e., optimizing the positions of a constant number of fixtures. However, how to determine the number of fixtures is ignored. In most cases, the number of fixtures located on large thin-walled parts is determined based on engineering experience, which leads to huge fixture number and extra waste. Therefore, this paper constructs an optimization model to minimize the number of fixtures. The constraints are set in the optimization model to ensure that the part deformation is within the surface profile tolerance. In addition, the assembly gap between two parts is also controlled. To conduct the optimization, this paper develops an improved particle swarm optimization (IPSO) algorithm by integrating the shrinkage factor and adaptive inertia weight. In the algorithm, particles are encoded according to the fixture position. Each dimension of the particle is assigned to a sub-region by constraining the optional position range of each fixture to improve the optimization efficiency. Finally, a case study on ship curved panel assembly is provided to prove that our method can optimize the number of fixtures while meeting the assembly quality requirements. This research proposes a method to optimize the number of fixtures, which can reduce the number of fixtures and achieve deformation control at the same time.

There are lots of researches on fixture layout optimization for large thin-walled parts. Current researches focus on the positioning problem, i.e., optimizing the positions of a constant number of fixtures. However, how to determine the number of fixtures is ignored. In most cases, the number of fixtures located on large thin-walled parts is determined based on engineering experience, which leads to huge fixture number and extra waste. Therefore, this paper constructs an optimization model to minimize the number of fixtures. The constraints are set in the optimization model to ensure that the part deformation is within the surface profile tolerance. In addition, the assembly gap between two parts is also controlled. To conduct the optimization, this paper develops an improved particle swarm optimization (IPSO) algorithm by integrating the shrinkage factor and adaptive inertia weight. In the algorithm, particles are encoded according to the fixture position. Each dimension of the particle is assigned to a sub-region by constraining the optional position range of each fixture to improve the optimization efficiency. Finally, a case study on ship curved panel assembly is provided to prove that our method can optimize the number of fixtures while meeting the assembly quality requirements. This research proposes a method to optimize the number of fixtures, which can reduce the number of fixtures and achieve deformation control at the same time.

2024, 37: 157.

doi: 10.1186/s10033-024-01131-4

Abstract:

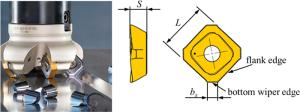

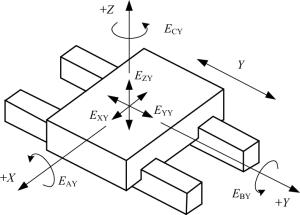

Wiper tools are revered for their capacity to simultaneously achieve high-quality and high-efficient machining. Nonetheless, the cutting mechanism of wiper tools remains unclear, and the cutting force prediction model of wiper tools has not been reported, leading to severe wear of the bottom wiper edge and unstable cutting in machining processes. In this study, the cutting mechanism of wiper tools is systematically analyzed, and the mechanistic cutting force model considering the wiper edge cutting effect was established. The cutting force coefficients were calibrated by the cutting force separation method, which can quickly calibrate the cutting force coefficients for the flank cutting region dominated by the shear effect, the bottom cutting region dominated by the shear effect, and the bottom wiper region dominated by plough effect. Compared with measured cutting forces, the maximum average absolute errors in the predicted forces are 9.2 %, 7.6 %, and 9.3 % in the x, y, and z directions, respectively. Furthermore, the feed rate and the length of the wiper edge were primary determinants of the bottom-edge cutting forces. This study provides theoretical guidance and technical support for the wear mechanism and design of wiper tools.

Wiper tools are revered for their capacity to simultaneously achieve high-quality and high-efficient machining. Nonetheless, the cutting mechanism of wiper tools remains unclear, and the cutting force prediction model of wiper tools has not been reported, leading to severe wear of the bottom wiper edge and unstable cutting in machining processes. In this study, the cutting mechanism of wiper tools is systematically analyzed, and the mechanistic cutting force model considering the wiper edge cutting effect was established. The cutting force coefficients were calibrated by the cutting force separation method, which can quickly calibrate the cutting force coefficients for the flank cutting region dominated by the shear effect, the bottom cutting region dominated by the shear effect, and the bottom wiper region dominated by plough effect. Compared with measured cutting forces, the maximum average absolute errors in the predicted forces are 9.2 %, 7.6 %, and 9.3 % in the x, y, and z directions, respectively. Furthermore, the feed rate and the length of the wiper edge were primary determinants of the bottom-edge cutting forces. This study provides theoretical guidance and technical support for the wear mechanism and design of wiper tools.

2024, 37: 51.

doi: 10.1186/s10033-024-01033-5

Abstract:

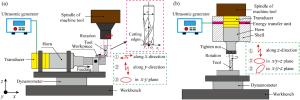

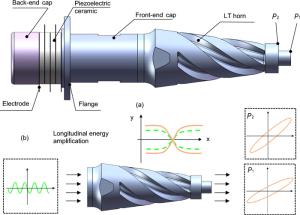

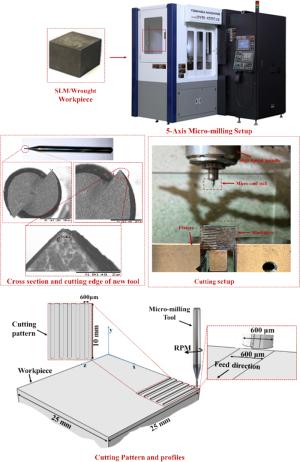

Textured surfaces with certain micro/nano structures have been proven to possess some advanced functions, such as reducing friction, improving wear and increasing wettability. Accurate prediction of micro/nano surface textures is of great significance for the design, fabrication and application of functional textured surfaces. In this paper, based on the kinematic analysis of cutter teeth, the discretization of ultrasonic machining process, transformation method of coordinate systems and the cubic spline data interpolation, an integrated theoretical model was established to characterize the distribution and geometric features of micro textures on the surfaces machined by different types of ultrasonic vibration-assisted milling (UVAM). Based on the theoretical model, the effect of key process parameters (vibration directions, vibration dimensions, cutting parameters and vibration parameters) on tool trajectories and microtextured surface morphology in UVAM is investigated. Besides, the effect of phase difference on the elliptical shape in 2D/3D ultrasonic elliptical vibration-assisted milling (UEVAM) was analyzed. Compared to conventional numerical models, the method of the cubic spline data interpolation is applied to the simulation of microtextured surface morphology in UVAM, which is more suitable for characterizing the morphological features of microtextured surfaces than traditional methods due to the presence of numerous micro textures. The prediction of surface roughness indicates that the magnitude of ultrasonic amplitude in z-direction should be strictly limited in 1D rotary UVAM, 2D and 3D UEVAM due to the unfavorable effect of axial ultrasonic vibration on the surface quality. This study can provide theoretical guidance for the design and fabrication of microtextured surfaces in UVAM.

Textured surfaces with certain micro/nano structures have been proven to possess some advanced functions, such as reducing friction, improving wear and increasing wettability. Accurate prediction of micro/nano surface textures is of great significance for the design, fabrication and application of functional textured surfaces. In this paper, based on the kinematic analysis of cutter teeth, the discretization of ultrasonic machining process, transformation method of coordinate systems and the cubic spline data interpolation, an integrated theoretical model was established to characterize the distribution and geometric features of micro textures on the surfaces machined by different types of ultrasonic vibration-assisted milling (UVAM). Based on the theoretical model, the effect of key process parameters (vibration directions, vibration dimensions, cutting parameters and vibration parameters) on tool trajectories and microtextured surface morphology in UVAM is investigated. Besides, the effect of phase difference on the elliptical shape in 2D/3D ultrasonic elliptical vibration-assisted milling (UEVAM) was analyzed. Compared to conventional numerical models, the method of the cubic spline data interpolation is applied to the simulation of microtextured surface morphology in UVAM, which is more suitable for characterizing the morphological features of microtextured surfaces than traditional methods due to the presence of numerous micro textures. The prediction of surface roughness indicates that the magnitude of ultrasonic amplitude in z-direction should be strictly limited in 1D rotary UVAM, 2D and 3D UEVAM due to the unfavorable effect of axial ultrasonic vibration on the surface quality. This study can provide theoretical guidance for the design and fabrication of microtextured surfaces in UVAM.

2024, 37: 60.

doi: 10.1186/s10033-024-01016-6

Abstract:

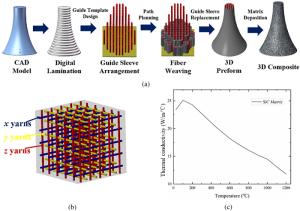

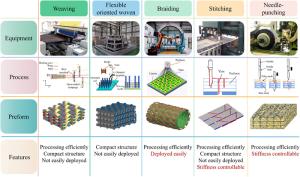

Thermal conductivity is one of the most significant criterion of three-dimensional carbon fiber-reinforced SiC matrix composites (3D C/SiC). Represent volume element (RVE) models of microscale, void/matrix and mesoscale proposed in this work are used to simulate the thermal conductivity behaviors of the 3D C/SiC composites. An entirely new process is introduced to weave the preform with three-dimensional orthogonal architecture. The 3D steady-state analysis step is created for assessing the thermal conductivity behaviors of the composites by applying periodic temperature boundary conditions. Three RVE models of cuboid, hexagonal and fiber random distribution are respectively developed to comparatively study the influence of fiber package pattern on the thermal conductivities at the microscale. Besides, the effect of void morphology on the thermal conductivity of the matrix is analyzed by the void/matrix models. The prediction results at the mesoscale correspond closely to the experimental values. The effect of the porosities and fiber volume fractions on the thermal conductivities is also taken into consideration. The multi-scale models mentioned in this paper can be used to predict the thermal conductivity behaviors of other composites with complex structures.

Thermal conductivity is one of the most significant criterion of three-dimensional carbon fiber-reinforced SiC matrix composites (3D C/SiC). Represent volume element (RVE) models of microscale, void/matrix and mesoscale proposed in this work are used to simulate the thermal conductivity behaviors of the 3D C/SiC composites. An entirely new process is introduced to weave the preform with three-dimensional orthogonal architecture. The 3D steady-state analysis step is created for assessing the thermal conductivity behaviors of the composites by applying periodic temperature boundary conditions. Three RVE models of cuboid, hexagonal and fiber random distribution are respectively developed to comparatively study the influence of fiber package pattern on the thermal conductivities at the microscale. Besides, the effect of void morphology on the thermal conductivity of the matrix is analyzed by the void/matrix models. The prediction results at the mesoscale correspond closely to the experimental values. The effect of the porosities and fiber volume fractions on the thermal conductivities is also taken into consideration. The multi-scale models mentioned in this paper can be used to predict the thermal conductivity behaviors of other composites with complex structures.

2024, 37: 30.

doi: 10.1186/s10033-024-01006-8

Abstract:

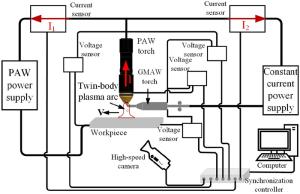

The twin-body plasma arc has the decoupling control ability of heat transfer and mass transfer, which is beneficial to shape and property control in wire arc additive manufacturing. In this paper, with the wire feeding speed as a characteristic quantity, the wire melting control ability of twin-body plasma arc was studied by adjusting the current separation ratio (under the condition of a constant total current), the wire current/main current and the position of the wire in the arc axial direction. The results showed that under the premise that the total current remains unchanged (100 A), as the current separation ratio increased, the middle and minimum melting amounts increased approximately synchronously under the effect of anode effect power, the first melting mass range remained constant; the maximum melting amount increased twice as fast as the middle melting amount under the effect of the wire feeding speed, and the second melting mass range was expanded. When the wire current increased, the anode effect power and the plasma arc power were both factors causing the increase in the wire melting amount; however, when the main current increased, the plasma arc power was the only factor causing the increase in the wire melting amount. The average wire melting increment caused by the anode effect power was approximately 2.7 times that caused by the plasma arc power. The minimum melting amount was not affected by the wire-torch distance under any current separation ratio tested. When the current separation ratio increased and reached a threshold, the middle melting amount remained constant with increasing wire-torch distance. When the current separation ratio continued to increase and reached the next threshold, the maximum melting amount remained constant with the increasing wire-torch distance. The effect of the wire-torch distance on the wire melting amount reduced with the increase in the current separation ratio. Through this study, the decoupling mechanism and ability of this innovative arc heat source is more clearly.

The twin-body plasma arc has the decoupling control ability of heat transfer and mass transfer, which is beneficial to shape and property control in wire arc additive manufacturing. In this paper, with the wire feeding speed as a characteristic quantity, the wire melting control ability of twin-body plasma arc was studied by adjusting the current separation ratio (under the condition of a constant total current), the wire current/main current and the position of the wire in the arc axial direction. The results showed that under the premise that the total current remains unchanged (100 A), as the current separation ratio increased, the middle and minimum melting amounts increased approximately synchronously under the effect of anode effect power, the first melting mass range remained constant; the maximum melting amount increased twice as fast as the middle melting amount under the effect of the wire feeding speed, and the second melting mass range was expanded. When the wire current increased, the anode effect power and the plasma arc power were both factors causing the increase in the wire melting amount; however, when the main current increased, the plasma arc power was the only factor causing the increase in the wire melting amount. The average wire melting increment caused by the anode effect power was approximately 2.7 times that caused by the plasma arc power. The minimum melting amount was not affected by the wire-torch distance under any current separation ratio tested. When the current separation ratio increased and reached a threshold, the middle melting amount remained constant with increasing wire-torch distance. When the current separation ratio continued to increase and reached the next threshold, the maximum melting amount remained constant with the increasing wire-torch distance. The effect of the wire-torch distance on the wire melting amount reduced with the increase in the current separation ratio. Through this study, the decoupling mechanism and ability of this innovative arc heat source is more clearly.

2024, 37: 101.

doi: 10.1186/s10033-024-01092-8

Abstract:

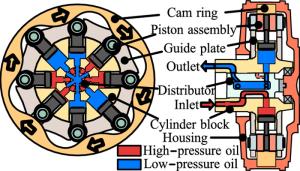

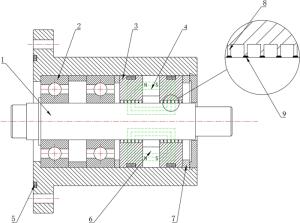

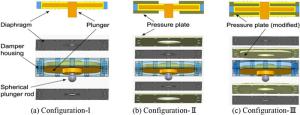

High-end equipment always operate in low-speed and heavy-load working environments, highlighting the need for cam-lobe hydraulic motors with excellent speed stability (< 1 r/min) and ultrahigh-power rotary output (> 1 MW). The successful operation of cam-lobe hydraulic motors relies on the circulation supply of high- and low-pressure oil. However, the switching between high-/low-pressure oil controlled by the oil distributor inevitably causes an obvious pressure impact and speed pulsation, which directly reduces the speed stability of hydraulic motors. Therefore, an optimization design approach for the oil distributor port is proposed to minimize the speed pulsation of cam-lobe hydraulic motors. In the proposed approach, a simulation model that links the oil distributor port structural parameters with the hydraulic motor speed pulsation was developed to clarify the effect of the oil distributor structural parameters on speed pulsation. Then, an orthogonal analysis method was used to identify the optimized oil distributor port structural parameters while minimizing the hydraulic motor's speed pulsation as much as possible. Finally, several experiments were conducted to validate the effectiveness and accuracy of the proposed optimization design approach. The experimental results indicate that the pulsation rate of the hydraulic motor equipped with the optimized oil distributor was 62.5% lower than that of the original motor at a working pressure of 25 MPa, which is consistent with the simulation results using the proposed optimization design approach. The findings of this study offer a feasible and effective approach to guide the design optimization of the oil distributor port for low-pulsation hydraulic motors.

High-end equipment always operate in low-speed and heavy-load working environments, highlighting the need for cam-lobe hydraulic motors with excellent speed stability (< 1 r/min) and ultrahigh-power rotary output (> 1 MW). The successful operation of cam-lobe hydraulic motors relies on the circulation supply of high- and low-pressure oil. However, the switching between high-/low-pressure oil controlled by the oil distributor inevitably causes an obvious pressure impact and speed pulsation, which directly reduces the speed stability of hydraulic motors. Therefore, an optimization design approach for the oil distributor port is proposed to minimize the speed pulsation of cam-lobe hydraulic motors. In the proposed approach, a simulation model that links the oil distributor port structural parameters with the hydraulic motor speed pulsation was developed to clarify the effect of the oil distributor structural parameters on speed pulsation. Then, an orthogonal analysis method was used to identify the optimized oil distributor port structural parameters while minimizing the hydraulic motor's speed pulsation as much as possible. Finally, several experiments were conducted to validate the effectiveness and accuracy of the proposed optimization design approach. The experimental results indicate that the pulsation rate of the hydraulic motor equipped with the optimized oil distributor was 62.5% lower than that of the original motor at a working pressure of 25 MPa, which is consistent with the simulation results using the proposed optimization design approach. The findings of this study offer a feasible and effective approach to guide the design optimization of the oil distributor port for low-pulsation hydraulic motors.

2024, 37: 41.

doi: 10.1186/s10033-024-01021-9

Abstract:

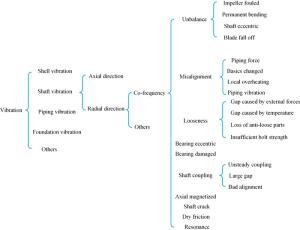

The co-frequency vibration fault is one of the common faults in the operation of rotating equipment, and realizing the real-time diagnosis of the co-frequency vibration fault is of great significance for monitoring the health state and carrying out vibration suppression of the equipment. In engineering scenarios, co-frequency vibration faults are highlighted by rotational frequency and are difficult to identify, and existing intelligent methods require more hardware conditions and are exclusively time-consuming. Therefore, Lightweight-convolutional neural networks (LW-CNN) algorithm is proposed in this paper to achieve real-time fault diagnosis. The critical parameters are discussed and verified by simulated and experimental signals for the sliding window data augmentation method. Based on LW-CNN and data augmentation, the real-time intelligent diagnosis of co-frequency is realized. Moreover, a real-time detection method of fault diagnosis algorithm is proposed for data acquisition to fault diagnosis. It is verified by experiments that the LW-CNN and sliding window methods are used with high accuracy and real-time performance.

The co-frequency vibration fault is one of the common faults in the operation of rotating equipment, and realizing the real-time diagnosis of the co-frequency vibration fault is of great significance for monitoring the health state and carrying out vibration suppression of the equipment. In engineering scenarios, co-frequency vibration faults are highlighted by rotational frequency and are difficult to identify, and existing intelligent methods require more hardware conditions and are exclusively time-consuming. Therefore, Lightweight-convolutional neural networks (LW-CNN) algorithm is proposed in this paper to achieve real-time fault diagnosis. The critical parameters are discussed and verified by simulated and experimental signals for the sliding window data augmentation method. Based on LW-CNN and data augmentation, the real-time intelligent diagnosis of co-frequency is realized. Moreover, a real-time detection method of fault diagnosis algorithm is proposed for data acquisition to fault diagnosis. It is verified by experiments that the LW-CNN and sliding window methods are used with high accuracy and real-time performance.

2024, 37: 151.

doi: 10.1186/s10033-024-01136-z

Abstract:

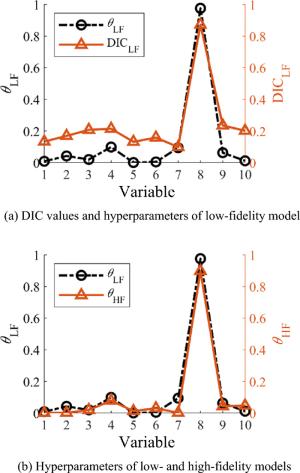

The multi-fidelity Kriging model is a promising technique in surrogate-based design, balancing model accuracy and the cost of sample generation by combining low- and high-fidelity data. However, the cost of building a multi-fidelity Kriging model increases significantly as problem complexity grows. To address this issue, we propose an efficient Hierarchical Kriging modeling method. In building the low-fidelity model, distance correlation is used to determine the relative value of the hyperparameter. This transforms the maximum likelihood estimation problem into a one-dimensional optimization task, which can be solved efficiently, significantly improving modeling efficiency. The high-fidelity model is built similarly, with the low-fidelity model's hyperparameter used as the relative value for the high-fidelity model's hyperparameter. The proposed method's effectiveness is evaluated through analytical problems and a real-world engineering problem involving modeling the isentropic efficiency of a compressor rotor. Experimental results show that the proposed method reduces modeling time significantly without compromising accuracy. For the compressor rotor isentropic efficiency model, the proposed method yields over 99% cost savings compared to conventional approaches, while also achieving higher accuracy.

The multi-fidelity Kriging model is a promising technique in surrogate-based design, balancing model accuracy and the cost of sample generation by combining low- and high-fidelity data. However, the cost of building a multi-fidelity Kriging model increases significantly as problem complexity grows. To address this issue, we propose an efficient Hierarchical Kriging modeling method. In building the low-fidelity model, distance correlation is used to determine the relative value of the hyperparameter. This transforms the maximum likelihood estimation problem into a one-dimensional optimization task, which can be solved efficiently, significantly improving modeling efficiency. The high-fidelity model is built similarly, with the low-fidelity model's hyperparameter used as the relative value for the high-fidelity model's hyperparameter. The proposed method's effectiveness is evaluated through analytical problems and a real-world engineering problem involving modeling the isentropic efficiency of a compressor rotor. Experimental results show that the proposed method reduces modeling time significantly without compromising accuracy. For the compressor rotor isentropic efficiency model, the proposed method yields over 99% cost savings compared to conventional approaches, while also achieving higher accuracy.

2024, 37: 92.

doi: 10.1186/s10033-024-01051-3

Abstract:

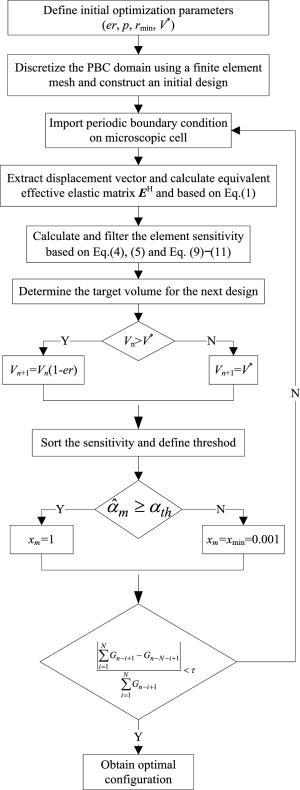

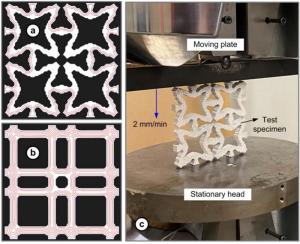

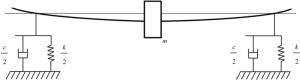

The current research of sandwich structures under dynamic loading mainly focus on the response characteristic of structure. The micro-topology of core layers would sufficiently influence the property of sandwich structure. However, the micro deformation and topology mechanism of structural deformation and energy absorption are unclear. In this paper, based on the bi-directional evolutionary structural optimization method and periodic base cell (PBC) technology, a topology optimization frame work is proposed to optimize the core layer of sandwich beams. The objective of the present optimization problem is to maximize shear stiffness of PBC with a volume constraint. The effects of the volume fraction, filter radius, and initial PBC aspect ratio on the micro-topology of the core were discussed. The dynamic response process, core compression, and energy absorption capacity of the sandwich beams under blast impact loading were analyzed by the finite element method. The results demonstrated that the over-pressure action stage was coupled with the core compression stage. Under the same loading and mass per unit area, the sandwich beam with a 20% volume fraction core layer had the best blast resistance. The filter radius has a slight effect on the shear stiffness and blast resistances of the sandwich beams. But increasing the filter radius could slightly improve the bending stiffness. Upon changing the initial PBC aspect ratio, there are three ways for PBC evolution: The first is to change the angle between the adjacent bars, the second is to further form holes in the bars, and the third is to combine the first two ways. However, not all three ways can improve the energy absorption capacity of the structure. Changing the aspect ratio of the PBC arbitrarily may lead to worse results. More studies are necessary for further detailed optimization. This research proposes a new topology sandwich beam structure by micro-topology optimization, which has sufficient shear stiffness. The micro mechanism of structural energy absorption is clarified, it is significant for structural energy absorption design.

The current research of sandwich structures under dynamic loading mainly focus on the response characteristic of structure. The micro-topology of core layers would sufficiently influence the property of sandwich structure. However, the micro deformation and topology mechanism of structural deformation and energy absorption are unclear. In this paper, based on the bi-directional evolutionary structural optimization method and periodic base cell (PBC) technology, a topology optimization frame work is proposed to optimize the core layer of sandwich beams. The objective of the present optimization problem is to maximize shear stiffness of PBC with a volume constraint. The effects of the volume fraction, filter radius, and initial PBC aspect ratio on the micro-topology of the core were discussed. The dynamic response process, core compression, and energy absorption capacity of the sandwich beams under blast impact loading were analyzed by the finite element method. The results demonstrated that the over-pressure action stage was coupled with the core compression stage. Under the same loading and mass per unit area, the sandwich beam with a 20% volume fraction core layer had the best blast resistance. The filter radius has a slight effect on the shear stiffness and blast resistances of the sandwich beams. But increasing the filter radius could slightly improve the bending stiffness. Upon changing the initial PBC aspect ratio, there are three ways for PBC evolution: The first is to change the angle between the adjacent bars, the second is to further form holes in the bars, and the third is to combine the first two ways. However, not all three ways can improve the energy absorption capacity of the structure. Changing the aspect ratio of the PBC arbitrarily may lead to worse results. More studies are necessary for further detailed optimization. This research proposes a new topology sandwich beam structure by micro-topology optimization, which has sufficient shear stiffness. The micro mechanism of structural energy absorption is clarified, it is significant for structural energy absorption design.

2024, 37: 55.

doi: 10.1186/s10033-024-01019-3

Abstract:

This paper presents a topology optimization approach for the surface flows on variable design domains. Via this approach, the matching between the pattern of a surface flow and the 2-manifold used to define the pattern can be optimized, where the 2-manifold is implicitly defined on another fixed 2-manifold named as the base manifold. The fiber bundle topology optimization approach is developed based on the description of the topological structure of the surface flow by using the differential geometry concept of the fiber bundle. The material distribution method is used to achieve the evolution of the pattern of the surface flow. The evolution of the implicit 2-manifold is realized via a homeomorphous map. The design variable of the pattern of the surface flow and that of the implicit 2-manifold are regularized by two sequentially implemented surface-PDE filters. The two surface-PDE filters are coupled, because they are defined on the implicit 2-manifold and base manifold, respectively. The surface Navier-Stokes equations, defined on the implicit 2-manifold, are used to describe the surface flow. The fiber bundle topology optimization problem is analyzed using the continuous adjoint method implemented on the first-order Sobolev space. Several numerical examples have been provided to demonstrate this approach, where the combination of the viscous dissipation and pressure drop is used as the design objective.

This paper presents a topology optimization approach for the surface flows on variable design domains. Via this approach, the matching between the pattern of a surface flow and the 2-manifold used to define the pattern can be optimized, where the 2-manifold is implicitly defined on another fixed 2-manifold named as the base manifold. The fiber bundle topology optimization approach is developed based on the description of the topological structure of the surface flow by using the differential geometry concept of the fiber bundle. The material distribution method is used to achieve the evolution of the pattern of the surface flow. The evolution of the implicit 2-manifold is realized via a homeomorphous map. The design variable of the pattern of the surface flow and that of the implicit 2-manifold are regularized by two sequentially implemented surface-PDE filters. The two surface-PDE filters are coupled, because they are defined on the implicit 2-manifold and base manifold, respectively. The surface Navier-Stokes equations, defined on the implicit 2-manifold, are used to describe the surface flow. The fiber bundle topology optimization problem is analyzed using the continuous adjoint method implemented on the first-order Sobolev space. Several numerical examples have been provided to demonstrate this approach, where the combination of the viscous dissipation and pressure drop is used as the design objective.

2024, 37: 166.

doi: 10.1186/s10033-024-01155-w

Abstract:

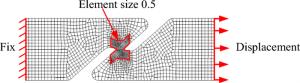

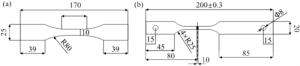

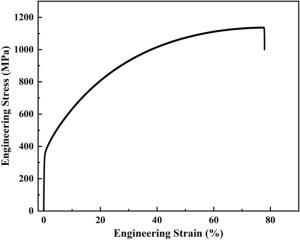

When a hydrogen storage vessel is subjected to a local impact load, damage may occur in the liner and result in hydrogen leakage and other catastrophic consequences. When predicting liner damage of a hydrogen storage vessel using the finite element method (FEM), although large element size is required to achieve a desired computational efficiency, it oftentimes causes inaccuracy in the damage model. To remedy this problem, in this study a novel approach which calculates the material damage based on the GISSMO (Generalized Incremental Stress State dependent damage Model) damage model and employs a submodeling strategy is proposed. According to this approach, the global model is discretized to large elements to increase the efficiency, while the submodel is meshed to much smaller elements to accurately reflect the material damage. Employing the established approach and material parameters calibrated from a large set of notched aluminum alloy 5083 specimens, the liner damage of a type Ⅲ hydrogen storage vessel subjected to a local compressive load was simulated. This way, the study reveals how the characteristics of the stress and material damage interact with each other. In addition, the study also demonstrates that the proposed approach can be used as a viable means to evaluate the damage within hydrogen storage vessels.

When a hydrogen storage vessel is subjected to a local impact load, damage may occur in the liner and result in hydrogen leakage and other catastrophic consequences. When predicting liner damage of a hydrogen storage vessel using the finite element method (FEM), although large element size is required to achieve a desired computational efficiency, it oftentimes causes inaccuracy in the damage model. To remedy this problem, in this study a novel approach which calculates the material damage based on the GISSMO (Generalized Incremental Stress State dependent damage Model) damage model and employs a submodeling strategy is proposed. According to this approach, the global model is discretized to large elements to increase the efficiency, while the submodel is meshed to much smaller elements to accurately reflect the material damage. Employing the established approach and material parameters calibrated from a large set of notched aluminum alloy 5083 specimens, the liner damage of a type Ⅲ hydrogen storage vessel subjected to a local compressive load was simulated. This way, the study reveals how the characteristics of the stress and material damage interact with each other. In addition, the study also demonstrates that the proposed approach can be used as a viable means to evaluate the damage within hydrogen storage vessels.

2024, 37: 148.

doi: 10.1186/s10033-024-01129-y

Abstract:

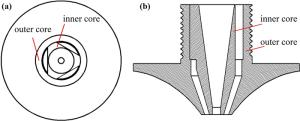

To optimize the magnetic fluid seal design, the single-factor method is usually used to study the effect of the rectangular pole teeth structure parameters on the sealing capacity of the magnetic fluid seal by current research, and the design formula is obtained. However, the supporting data is too few to make the results universalizable. In this paper, to obtain a wider range of applicable design formulas, a large number of modeling and simulation experiments are conducted using the co-simulation analysis experimental method of MATLAB and COMSOL. The influence of structure parameters of rectangular pole teeth and the coupling effects of the structure parameters on the sealing capacity of sealing devices has been studied under different lengths of pole piece (Lp) and seal gap (Lg). The results explain the influences of tooth height (Lh), tooth width (Lt), groove width (Ls), and their coupling effects on the theoretical sealing capacity of magnetic fluid seals, and more widely applicable design formulas for pole teeth structure parameters are given. The design formulas can help to obtain good design parameters directly or reduce the optimization range when the magnetic fluid seals need to be optimized to meet the miniaturization and lightweight requirements of magnetic fluid sealing devices or improve the sealing capacity under the same seal size.

To optimize the magnetic fluid seal design, the single-factor method is usually used to study the effect of the rectangular pole teeth structure parameters on the sealing capacity of the magnetic fluid seal by current research, and the design formula is obtained. However, the supporting data is too few to make the results universalizable. In this paper, to obtain a wider range of applicable design formulas, a large number of modeling and simulation experiments are conducted using the co-simulation analysis experimental method of MATLAB and COMSOL. The influence of structure parameters of rectangular pole teeth and the coupling effects of the structure parameters on the sealing capacity of sealing devices has been studied under different lengths of pole piece (Lp) and seal gap (Lg). The results explain the influences of tooth height (Lh), tooth width (Lt), groove width (Ls), and their coupling effects on the theoretical sealing capacity of magnetic fluid seals, and more widely applicable design formulas for pole teeth structure parameters are given. The design formulas can help to obtain good design parameters directly or reduce the optimization range when the magnetic fluid seals need to be optimized to meet the miniaturization and lightweight requirements of magnetic fluid sealing devices or improve the sealing capacity under the same seal size.

2024, 37: 170.

doi: 10.1186/s10033-024-01101-w

Abstract:

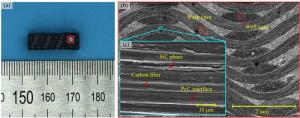

Cf/SiC composites are characterized as anisotropic, heterogeneous, brittle, and hard materials. The process of manufacturing Cf/SiC composites using traditional machining techniques is prone to edge chipping damage and tool wear, which makes it difficult to meet the machining quality and machining accuracy. The purpose of this paper is to investigate the milling characteristics and damage assessment during ultrasonic vibration-assisted end milling (UVAEM) of Cf/SiC composites. Firstly, UVAEM experiments on Cf/SiC composites were carried out at different ultrasonic amplitudes and comparative experiments with conventional milling (CM). In addition, tool wear, surface roughness, surface micromorphology, milling force and subsurface damage (SSD) were measured and analysed. Finally, the SSD factors of Cf/SiC composites were established to quantify machining damage, and analyzed the effect of ultrasonic amplitude on SSD. Furthermore, the formation mechanism of SSD was investigated and discussed. The findings indicate that appropriate ultrasonic amplitude improves the surface quality by UVAEM, while excessive amplitude deteriorates the surface quality. During the UVAEM, micro/macro brittle fracture of the fibers on the surface occurs, leading to machining defects such as fiber breakage, fiber-interface debonding and pits. The milling force gradually decreases with the increase of ultrasonic amplitude. On the other hand, the forms of SSD in CM and UVAEM are mainly fiber pullout, subsurface crack, crack extension and machining pits. Matrix cracking and fiber pullout in SSD were affected by fiber orientation. Moreover, the introduction of ultrasonic vibration plays a significant contribution in the inhibition of the SSD in Cf/SiC composites.

Cf/SiC composites are characterized as anisotropic, heterogeneous, brittle, and hard materials. The process of manufacturing Cf/SiC composites using traditional machining techniques is prone to edge chipping damage and tool wear, which makes it difficult to meet the machining quality and machining accuracy. The purpose of this paper is to investigate the milling characteristics and damage assessment during ultrasonic vibration-assisted end milling (UVAEM) of Cf/SiC composites. Firstly, UVAEM experiments on Cf/SiC composites were carried out at different ultrasonic amplitudes and comparative experiments with conventional milling (CM). In addition, tool wear, surface roughness, surface micromorphology, milling force and subsurface damage (SSD) were measured and analysed. Finally, the SSD factors of Cf/SiC composites were established to quantify machining damage, and analyzed the effect of ultrasonic amplitude on SSD. Furthermore, the formation mechanism of SSD was investigated and discussed. The findings indicate that appropriate ultrasonic amplitude improves the surface quality by UVAEM, while excessive amplitude deteriorates the surface quality. During the UVAEM, micro/macro brittle fracture of the fibers on the surface occurs, leading to machining defects such as fiber breakage, fiber-interface debonding and pits. The milling force gradually decreases with the increase of ultrasonic amplitude. On the other hand, the forms of SSD in CM and UVAEM are mainly fiber pullout, subsurface crack, crack extension and machining pits. Matrix cracking and fiber pullout in SSD were affected by fiber orientation. Moreover, the introduction of ultrasonic vibration plays a significant contribution in the inhibition of the SSD in Cf/SiC composites.

2024, 37: 163.

doi: 10.1186/s10033-024-01148-9

Abstract:

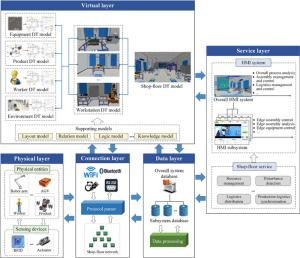

In recent years, the rapid development of large-scale satellite constellations has challenged the mass production capabilities of satellite manufacturers. Assembly is the last and critical phase of satellite production. Achieving satellite mass assembly is the key to realizing satellite mass production. To this end, satellite manufacturers are working to construct the satellite mass assembly shop-floor (SMAS) to enable moving assembly. However, there is still a lack of a modularized manufacturing system oriented to flexible production for SMAS, as well as disturbance detection methods and production-logistics synchronization methods to deal with various disturbances. Therefore, this paper proposes a digital twin-based production-logistics synchronization system (DT-PLSS) for SMAS. The framework of DT-PLSS is introduced first. In this framework, DT-PLSS can achieve modular construction, as well as distributed management and control. Based on the proposed framework, the construction methods of resource level digital twin (DT), workstation level DT, and shop-floor level DT in SMAS are discussed. The DT-based disturbance detection method for SMAS is presented, aiming to detect or predict different types of disturbances and to analyze the effect of disturbances. Then, a DT enhanced production-logistics synchronization mechanism for SMAS is proposed. With this mechanism, the logistics distribution in the dynamic shop-floor environment and production-logistics synchronization under various disturbances can be realized. Finally, a case study in a real SMAS verifies the feasibility and effectiveness of the proposed system and methods. This research proposes a practical framework and system which could realize disturbance detection, logistics distribution, and the production-logistics synchronization in complex SMAS scenario effectively.

In recent years, the rapid development of large-scale satellite constellations has challenged the mass production capabilities of satellite manufacturers. Assembly is the last and critical phase of satellite production. Achieving satellite mass assembly is the key to realizing satellite mass production. To this end, satellite manufacturers are working to construct the satellite mass assembly shop-floor (SMAS) to enable moving assembly. However, there is still a lack of a modularized manufacturing system oriented to flexible production for SMAS, as well as disturbance detection methods and production-logistics synchronization methods to deal with various disturbances. Therefore, this paper proposes a digital twin-based production-logistics synchronization system (DT-PLSS) for SMAS. The framework of DT-PLSS is introduced first. In this framework, DT-PLSS can achieve modular construction, as well as distributed management and control. Based on the proposed framework, the construction methods of resource level digital twin (DT), workstation level DT, and shop-floor level DT in SMAS are discussed. The DT-based disturbance detection method for SMAS is presented, aiming to detect or predict different types of disturbances and to analyze the effect of disturbances. Then, a DT enhanced production-logistics synchronization mechanism for SMAS is proposed. With this mechanism, the logistics distribution in the dynamic shop-floor environment and production-logistics synchronization under various disturbances can be realized. Finally, a case study in a real SMAS verifies the feasibility and effectiveness of the proposed system and methods. This research proposes a practical framework and system which could realize disturbance detection, logistics distribution, and the production-logistics synchronization in complex SMAS scenario effectively.

2024, 37: 27.

doi: 10.1186/s10033-023-00988-1

Abstract:

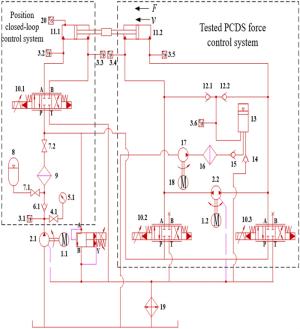

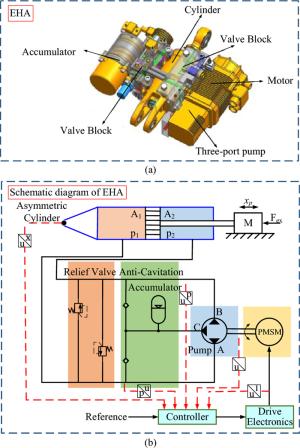

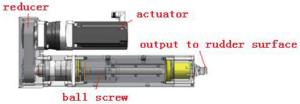

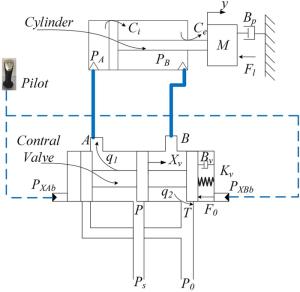

Each joint of a hydraulic-driven legged robot adopts a highly integrated hydraulic drive unit (HDU), which features a high power–weight ratio. However, most HDUs are throttling-valve-controlled cylinder systems, which exhibit high energy losses. By contrast, pump control systems offer a high efficiency. Nevertheless, their response ability is unsatisfactory. To fully utilize the advantages of pump and valve control systems, in this study, a new type of pump–valve compound drive system (PCDS) is designed, which can not only effectively reduce the energy loss, but can also ensure the response speed and response accuracy of the HDUs in robot joints to satisfy the performance requirements of robots. Herein, considering the force control requirements of energy conservation, high precision, and fast response of the robot joint HDU, a nonlinear mathematical model of the PCDS force control system is first introduced. In addition, pressure–flow nonlinearity, friction nonlinearity, load complexity and variability, and other factors affecting the system are considered, and a novel force control method based on quantitative feedback theory (QFT) and a disturbance torque observer (DTO) is designed, which is denoted as QFT–DTOC herein. This method improves the control accuracy and robustness of the force control system, reduces the effect of the disturbance torque on the control performance of the servo motor, and improves the overall force control performance of the system. Finally, experimental verification is performed using the PCDS performance test platform. The experimental results and quantitative data show that the QFT–DTOC proposed herein can significantly improve the force control performance of the PCDS. The relevant force control method can be used as a bottom-control method for the hydraulic servo system to provide a foundation for implementing the top-level trajectory planning of the robot.

Each joint of a hydraulic-driven legged robot adopts a highly integrated hydraulic drive unit (HDU), which features a high power–weight ratio. However, most HDUs are throttling-valve-controlled cylinder systems, which exhibit high energy losses. By contrast, pump control systems offer a high efficiency. Nevertheless, their response ability is unsatisfactory. To fully utilize the advantages of pump and valve control systems, in this study, a new type of pump–valve compound drive system (PCDS) is designed, which can not only effectively reduce the energy loss, but can also ensure the response speed and response accuracy of the HDUs in robot joints to satisfy the performance requirements of robots. Herein, considering the force control requirements of energy conservation, high precision, and fast response of the robot joint HDU, a nonlinear mathematical model of the PCDS force control system is first introduced. In addition, pressure–flow nonlinearity, friction nonlinearity, load complexity and variability, and other factors affecting the system are considered, and a novel force control method based on quantitative feedback theory (QFT) and a disturbance torque observer (DTO) is designed, which is denoted as QFT–DTOC herein. This method improves the control accuracy and robustness of the force control system, reduces the effect of the disturbance torque on the control performance of the servo motor, and improves the overall force control performance of the system. Finally, experimental verification is performed using the PCDS performance test platform. The experimental results and quantitative data show that the QFT–DTOC proposed herein can significantly improve the force control performance of the PCDS. The relevant force control method can be used as a bottom-control method for the hydraulic servo system to provide a foundation for implementing the top-level trajectory planning of the robot.

2024, 37: 162.

doi: 10.1186/s10033-024-01147-w

Abstract:

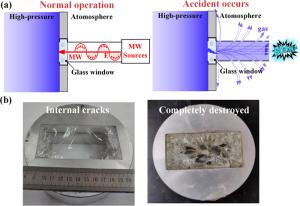

Currently, a 2-port microwave transmission line with a glass window is usually used to transmit microwave energy to a pressure vessel while sealing the high-pressure gas. In this situation, the damage of the brittle glass window will inevitably result in disastrous accidents. In this paper, the idea of a "2+4"-port microwave transmission line is first proposed to solve this problem. A 4-port waveguide bridge structure is connected to the input port of a traditional 2-port structure, which can release the high-pressure gas safely when the glass window of the 2-port microwave transmitting structure fails. To test this idea, a "2+4"-port microwave transmission line at 2.45 GHz was designed and fabricated. The effectiveness of the whole system in microwave transmission was validated by both simulations and experiments. A high microwave transmittance of more than 97% in the simulation and 91% in the experiment was achieved. The long-time transmission of 15-kW microwave energy, 5 times higher than the previous work, was realized. Moreover, the effectiveness of the transmission line in releasing high-pressure gas (0.6 MPa) was validated by a series of fluid-structure interaction simulations. This research proposes a new transmission structure for transmitting microwave into a pressurized environment safely and efficiently, which can be promoted to a series of applications including vacuum electron devices, microwave ovens, and so on.

Currently, a 2-port microwave transmission line with a glass window is usually used to transmit microwave energy to a pressure vessel while sealing the high-pressure gas. In this situation, the damage of the brittle glass window will inevitably result in disastrous accidents. In this paper, the idea of a "2+4"-port microwave transmission line is first proposed to solve this problem. A 4-port waveguide bridge structure is connected to the input port of a traditional 2-port structure, which can release the high-pressure gas safely when the glass window of the 2-port microwave transmitting structure fails. To test this idea, a "2+4"-port microwave transmission line at 2.45 GHz was designed and fabricated. The effectiveness of the whole system in microwave transmission was validated by both simulations and experiments. A high microwave transmittance of more than 97% in the simulation and 91% in the experiment was achieved. The long-time transmission of 15-kW microwave energy, 5 times higher than the previous work, was realized. Moreover, the effectiveness of the transmission line in releasing high-pressure gas (0.6 MPa) was validated by a series of fluid-structure interaction simulations. This research proposes a new transmission structure for transmitting microwave into a pressurized environment safely and efficiently, which can be promoted to a series of applications including vacuum electron devices, microwave ovens, and so on.

2024, 37: 75.

doi: 10.1186/s10033-024-01049-x

Abstract:

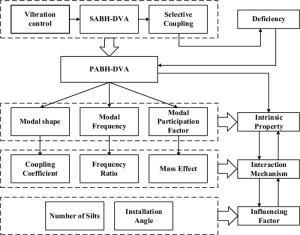

Vibration quality is a vital indicator for assessing the progress of modern equipment. The dynamic vibration absorber (DVA) based on the acoustic black hole (ABH) feature is a new passive control method that manipulates waves. It offers efficient energy focalization and broad-spectrum vibration suppression, making it highly promising for applications in large equipment such as aircraft, trains, and ships. Despite previous advancements in ABH-DVA development, certain challenges remain, particularly in ensuring effective coupling with host structures during control. To address these issues, this study proposes a partitioned ABH-featured dynamic vibration absorber (PABH-DVA) with partitions in the radial direction of the disc. By employing a plate as the host structure, simulations and experiments were conducted, demonstrating that the PABH-DVA outperforms the original symmetric ABH-DVA in terms of damping performance. The study also calculated and compared the coupling coefficients of the two ABH-DVAs to uncover the mechanism behind the enhanced damping. Simulation results revealed that the PABH-DVA exhibits more coupled modes, occasionally with lower coupling coefficients than the symmetric ABH-DVA. The influence of frequency ratio and modal mass was further analyzed to explain the reasons behind the PABH-DVA's superior damping performance. Additionally, the study discussed the impact of the number of slits and their orientation. This research further explains the coupling mechanism between the ABH-DVA and the controlled structure, and provides new ideas for the further application of ABH in engineering.